Tablets of Boiled linseed Oil

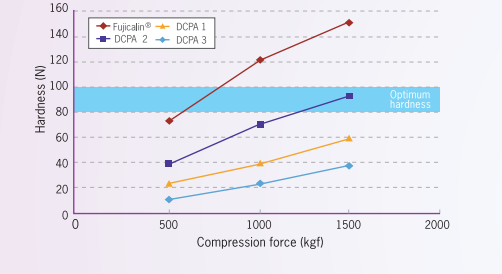

Converting oily actives into a free flowing powder which can be processed into capsules or tablets is a great challenge to formulators. The oil load may affect flowability, compactability and compressibility leading to poor quality tablets. Boiled linseed oil, a recommended oil for testing oil adsorption properties, was adsorbed on to Fujicalin® and other available DCPA’s. Fujicalin® showed excellent compressibility by achieving an optimum tablet hardness of 80 to 100 N at very low compression forces.

Tablet hardness of Fujicalin® and other commercially available DCPAs at different compression forces (ø11.3mm, 600 mg per tablet)

Tablets of Vitamin E

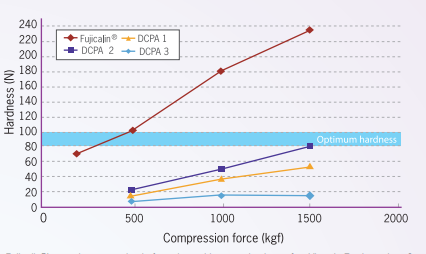

Vitamin E is a fat soluble vitamin like A, D and K. It is oily in physical appearance and exists either in the form of tocopherols or tocotrienols. 12.5 g of Vitamin E was diluted with same amount of ethanol and mixed well before loading on to 83.5 g of Fujicalin® or other grades of DCPAs. The mixture was dried overnight in an oven at 50ºC. Fujicalin® produced high quality Vitamin E tablets with sufficient tablet hardness (80-100 N) at low compression forces of 200-500 kgf. To achieve an optimum hardness of 80-100 N, other DCPA’s need to be compressed at higher forces.

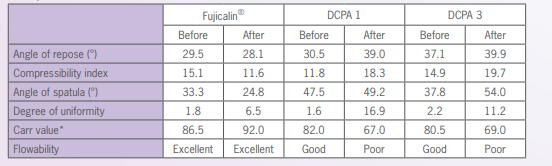

Powder characteristics after 12.5% Vitamin E load

Comparison data with other DCPAs

*Carr value calculated adding relevant index points. Higher value indicates better powder flow properties (Ref- Carr, R. L., Chem. Eng., 1965; 72(3), 163-168)

Tablet hardness after Vitamin E adsorption

Comparison data with other DCPAs

Fujicalin®’s powder properties in fact showed improved values after Vitamin E adsorption. Superior Carr value validates the efficiency of Fujicalin® in converting oily actives like vitamin E into a free flowing powder when compared to other DCPA’s.