Fujicalin® is a dibasic calcium phosphate anhydrous designed to function as a direct compression excipient.

It has exceptional flow and compression characteristics while maintaining the ability for rapid disintegration.

The key to Fujicalin®’s superior performance is the highly specialized and proprietary manufacturing process that yields a unique primary particle.

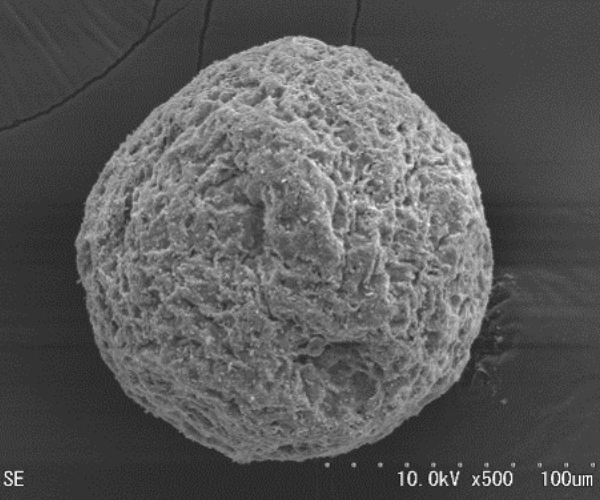

The patented manufacturing process yields porous spheres with high specific surface area. Fujicalin® is totally synthetic and ideally suited to direct compression formulations, especially involving difficult-to-compress materials like oily actives.

It can also be used to assist flow, reduce tablet weight variation and improve content uniformity.

Fujicalin®’s compressibility facilitates the design of smaller tablets. It can also be used as a partial or total replacement for microcrystalline cellulose.

General Properties

| Properties | Fujicalin® | |

| Appearance | White Crystalline Powder | |

| Mean particle size(µm) | 120 | |

| Bulk density(g/ml) | Loose | 0.46 |

| Tapped | 0.54 | |

| Compressibility index | 15.1 | |

| Angle of repose(°) | 29.5 | |

| Angle of spatula(°) | 33.3 | |

| Carr value* | 86.5 | |

| BET surface area(m²/g) | 40 | |

| Oil adsorption capacity(ml/g) | 1.1 | |

| Water adsorption capacity(ml/g) | 1.2 | |

| Loss on drying | 0.5 | |

| Flowability | Excellent | |

| Watter activity | 0.11 | |

*Carr value calculated adding relevant index points. Higher value indicates better powder flor properties

(Ref-Carr,R.L., Chem. Eng., 1965; 72(3), 163-168)

Unique attributes of Fujicalin®

Anhydrous Dibasic Calcium Phosphate is generally used as an excipient with low reactivity due to its neutral pH in the aqueous suspension. It also as a high bulk density and is not moisture sensitive as other excipients.

However, compressibility of conventional anhydrous calcium hydrogen phosphate are not sufficient for the direct compression.

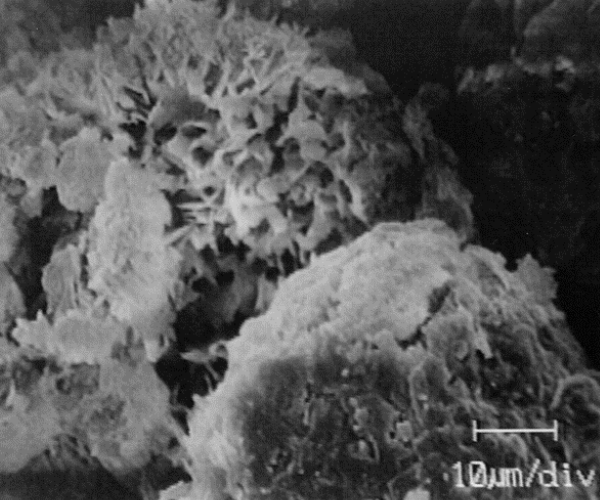

Fujicalin® has a spherical granule formed by spray-drying. It is also synthesized by a unique crystal growth control method. Fujicalin® has a crystalline structure of anhydrous calcium hydrogen phosphate, but the X-ray analysis pattern is broad due to the unique synthesis process. The primary particles are fine and plate-like.

With spray drying, plate-like crystals form a card house structure and resulting in granules with a large porosity. This structure produces the characteristics of Fujicalin (compressibility and oil absorption) that a conventional anhydrous dibasic calcium phosphate does not have, and is particularly suitable for direct compression.

Comparison of physical properties with conventional DCPA’s and DCPD

| Property | DCPA ( dibasic calcium phosphate, anhydrous ) | DCPD (dibasic calcium phosphate, dihydrate) |

|

| Fujicalin | Conventional DCPA | ||

| Average particle size* | 120μm | 45μm | 127μm |

| Bulk Density(Loose) | 0.46g/mL | 0.77g/mL | 0.83g/mL |

| Bulk Density(Tapped) | 0.54mg/mL | 1.11g/mL | 0.91g/mL |

| Angle of Repose | 30° | 42° | 35° |

| BET Surface area | 40m²/g | 0.7m²/g | 0.57m²/g |

| Oil Adsorption Capacity | 1.1mL/g | 0.4mL/g | 0.2mL/g |

| Water Adsorption | 1.2mL/g | 0.5mL/g | 0.2mL/g |

*Sieving Method

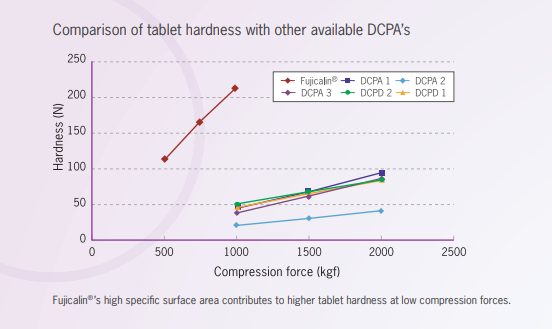

Comparison of tablet hardness with conventional DCPA’s and DCPD

DCPA:dibasic calcium phosphate, anhydrous

DCPD:dibasic calcium phosphate, dihydrate

Summary

- Fujicalin® retains porosity at high compression forces and exhibits low friability across broad compression range

- High porosity is maintained after compression

- Highly flowable and promotes content uniformity

- It can improve disintegration by triggering capillary action. With a right disintegrant, it can create fast disintegration tablets.

- Fujicalin®’s smooth and spherical granules are less abrasive on tableting machines leading to trouble free operations.

Application of Fujicalin®

Fujicalin is used for these applications utilizing the aforementioned attributes

- Fujicalin® makes sufficiently hard tablets at low compression forces, and it has a very low water content in addition. It is an ideal excipient for manufacturing tablets of probiotic preparations

- disintegration tablets using Fujicalin have already been launched commercially. Fujicalin has ability to promote disintegration.

- Fujicalin® is ideal as a carrier for Self-Emulsifying Drug Delivery System (SEDDS) and solid dispersion including Hot Melt Extrusion (HME).

- There have been roller compaction applications utilizing Fujicalin and micro crystalline cellulose