Neusilin increases the tablet hardness while enhancing disintegration

Compressibility

Neusilin® can improve compressibility and flow to ensure tablet hardness and minimum tablet weight variation

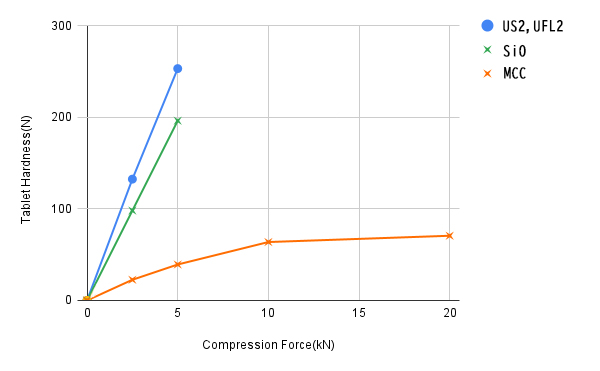

Compressibility of Neusilin

US2 and UFL2 are the best candidates for increasing tablet hardness.

US2 is spray dried granules, and UFL2 is the finely powderized grade.

We would like to introduce the examples of how Neusilin can enhance the tablet hardness. In all the examples, small amounts are sufficient to increase the tablet hardness.

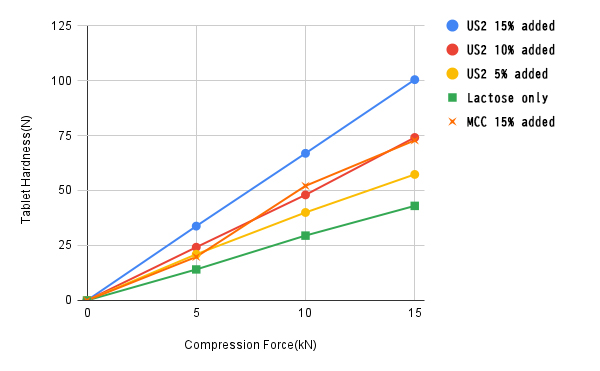

UFL2 addition to lactose (direct compression)

Neusilin alone would create hard tablets. However, adding 5-15% of Neusilin is sufficient to increase the tablet hardness.

Formulation:

- 5-15% lactose is added to lactose. MCC is used for comparison. 1% magnesium stearate is added to each formulation

Tabletting:

- Rotary Tableting Machine (500mg/T, 11mm diameter)

Result:

- Excellent tablet hardness is achieved. The result was proportional to the compression pressure (10-15% of Neusillin US2 is added.)

- Neusilin helped to create a more robust tablet with less amount (compared to MCC. ) 15% MCC had to be added to achieve the tablet hardness 10% US2 had achieved.

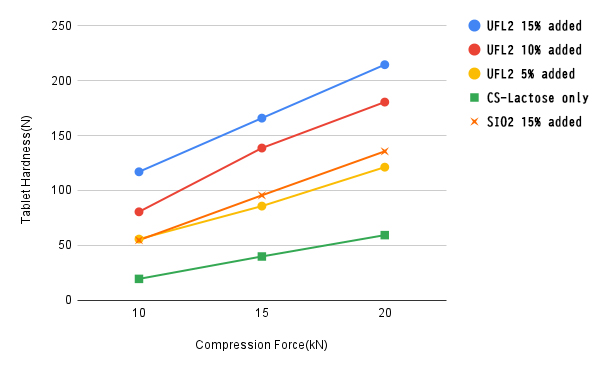

Comparison of compressibility of UFL2 with corn starch-lactose compound.

Neusilin can also increase the hardness of tablets under wet-granulation methods. The below graph indicates tablet hardness when Neusilin UFL2 was added to corn starch and lactose compound.

Formulation:

- 5-15% of lactose was added to corn starch and lactose formula (70/30).

- The above formulation is blended and kneaded with ion-exchanged water. Granules are prepared by extrusion and dried. 0.5% magnesium stearate is added to the granules.

Tableting:

- Tableting tester was used. (500mg/T, 11.3mm)

Result:

- The robust tablets were created with addition of Neusilin UFL2. The tablet hardness was proportional to the compression pressure

- The same study was conducted with silica. Neusilin UFL2 has achieved a higher tablet hardness with less amount compared to the silica.

Disintegration

Neusilin UFL2 intakes water through its pores. The capillary action enables to promote disintegration of tablets.

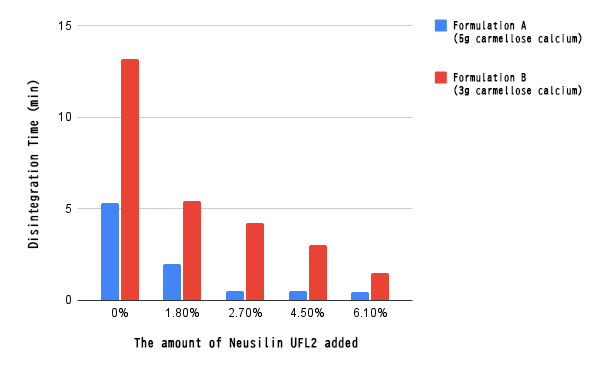

We have prepared a lactose-based formulation with methylcellulose(binder) and carmellose calcium (disintegrant,) and added Neusilin UFL2 for disintegration enhancement. The below graph shows the result.

Formulation:

- Formulation A- Lactose:85g, methycellose:15g, carmellose calcium: 5g, Magnesium stearate: 2g

- Formulation B- Lactose:85g, methycellose:15g, carmellose calcium: 3g, Magnesium stearate: 2g

Result and observation:

The disintegration time prolongs if no Neusilin is added. The wettability is compromised by a polymer barrier, which is created by methylcellose upon compression.

However, the addition of Neusilin improves the disintegration with the capillary action through its micro pores. Neusilin can accelerate the disintegration when a formulation contains a substance that creates an adhesive barrier.

Application in orally disintegrating tablets

Neusilin is used for another Fuji excipient: F-Melt®, which is a unique co-processed excipient for orally disintegrating tablets.

Neusilin can achieve a high tablet hardness with low compression force while promoting fast disintegration. It is very suited for formulation of orally disintegrating tablets. Also, Neusilin has anti-caking properties and suited for maintaining tablet hardness and fast disintegration after being stored under high-humidity conditions.