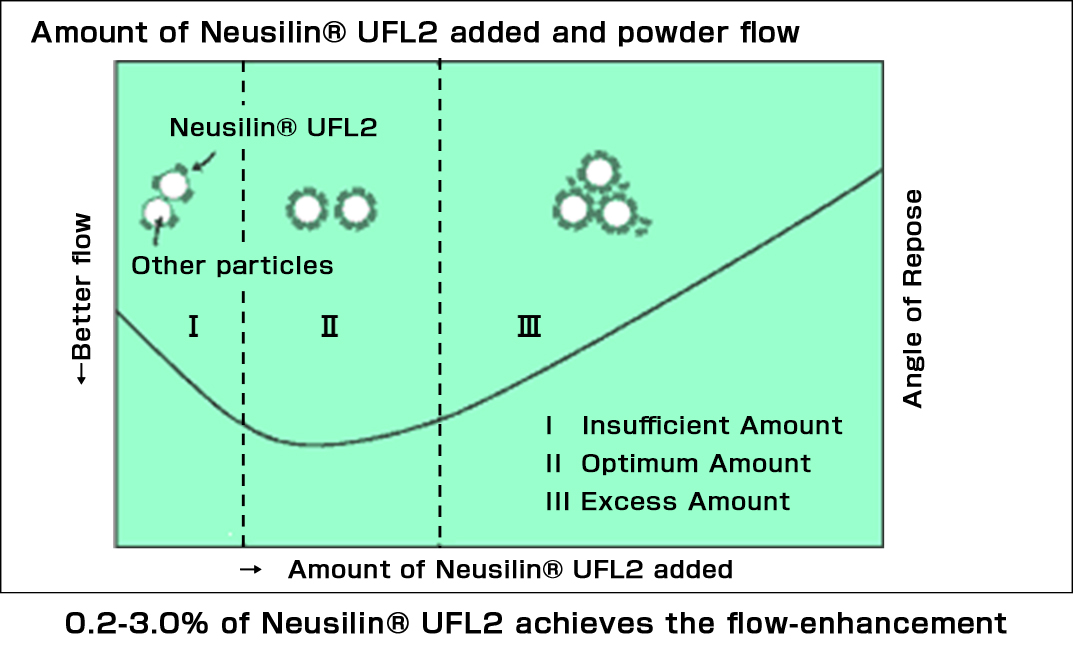

A small amount of Neusilin can improve powder flow.

Mechanism of flow enhancement

Powder flow issue is caused by adhesion and friction among powder. Adding0.2-3.0% of Neusilin ® UFL2stick to the surface of other powder and facilitate flow as in a ‘roller blade’ model.

The effect is minimum if a sufficient amount of Neusilin® UFL2is not added. On the other hand, an excess amount would jeopardize the effect. In some cases, 0.2% might be adequate. However, we recommend more than 0.5% to achieve the flow enhancement.

Surface Morphology

Electron micrograph showing Neusilin® UFL2 particles sticking to the starch surface. On addition to starch, the UFL2 particles stick to the surface and facilitate flow as in a ‘roller blade’ model. A 0.5% addition of UFL2 to potato starch vastly improves flowability.

Before adding UFL2

Neusilin® UFL2 addition and flow through an orifice.

The data of the UFL2 addition to potato starch is shown in the green line. Addition of 0.5% would decrease the diameter of the orifice from 30mm to approximately 4mm vastly improving the fluidity. However, addition of excessive amount would compromises fluidity improvement (the particle that did not adhere to the surface can interfere with the powder flow.)

Examples of Fluidity Improvement

Some examples of flow-enhancement by Neusilin® are shown below.

Flow Improvement of Ibuprofen Powder (video)

1% addition of Neusilin UFL2 vastly improves the flow

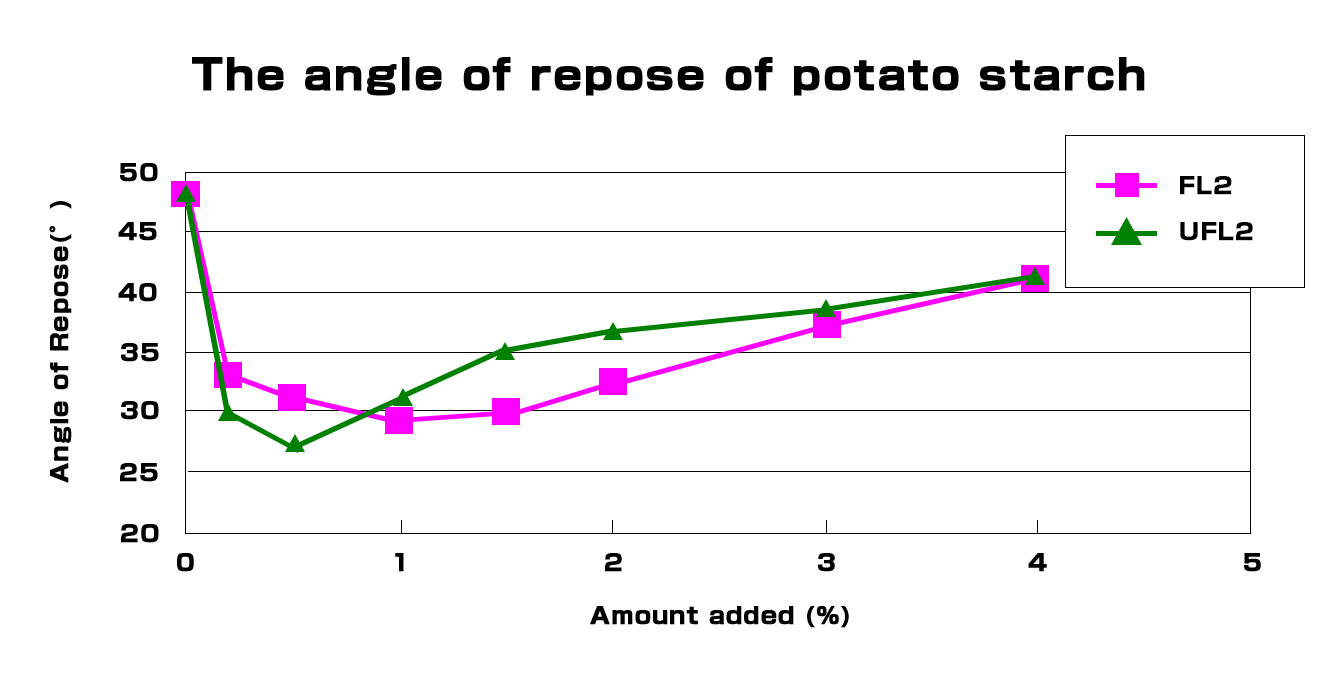

Comparison of fluidity improvement by grade

The most suited grade for flow enhancement is UFL2. However, other grades can improve fluidity of powder as well.

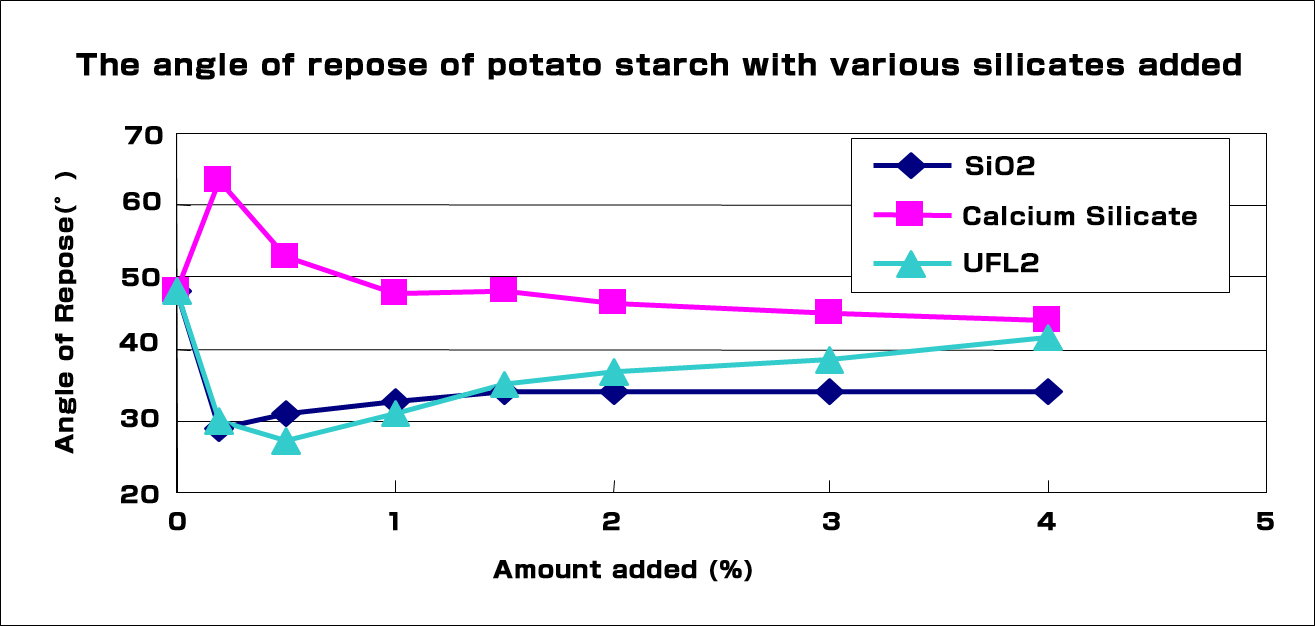

Flow-enhancement Comparison with other silicates

An appropriate amount of Neusilin® UFL2 supports easy manufacturing without downsides. The below graph indicate how the right amount of Neusilin® can support the flow compared with other silica.